Transitioning from HPS to LED

5 grow system variables to manage when transitioning from HPS to LED

Vapor Pressure Deficit (VPD)

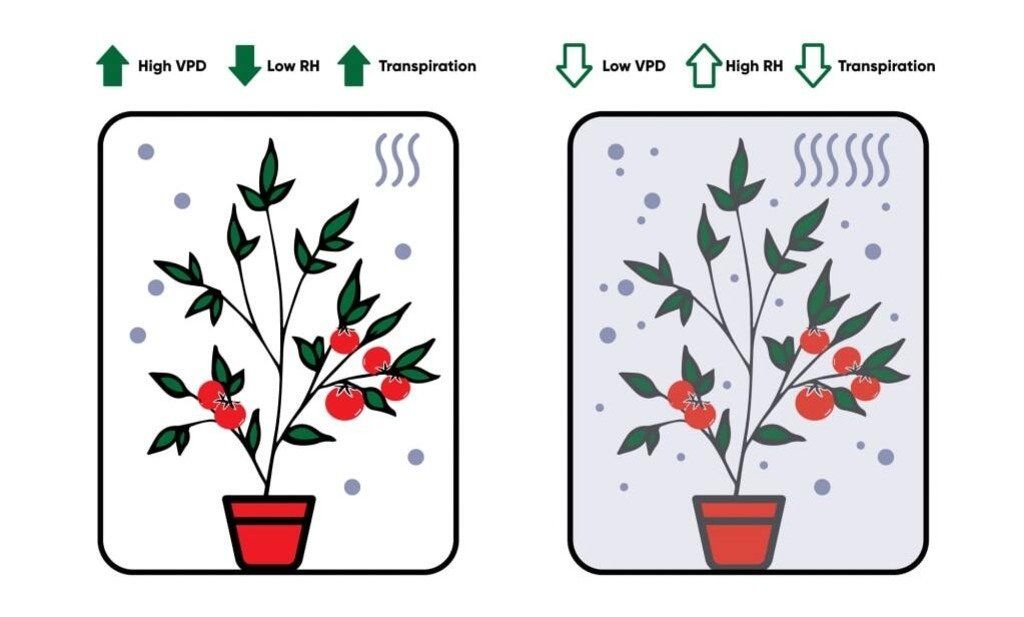

The key factors to control the plant transpiration and diseases occurrences are, environmental temperature, air moisture and ΔVPD. VPD is affected (function) by humidity and temperature levels.

As you decide to raise the temperature of your grow system, the humidity levels should be adjusted accordingly to the correct VPD range.

VPD translates the difference between the quantity of available air components (O2, water vapor, CO2 and others) and the quantity that the air can sustain of those components. Plant transpiration is dependent on the ΔVPD = VPDPlant– VPDAir for a fixed air temperature and humidity value.

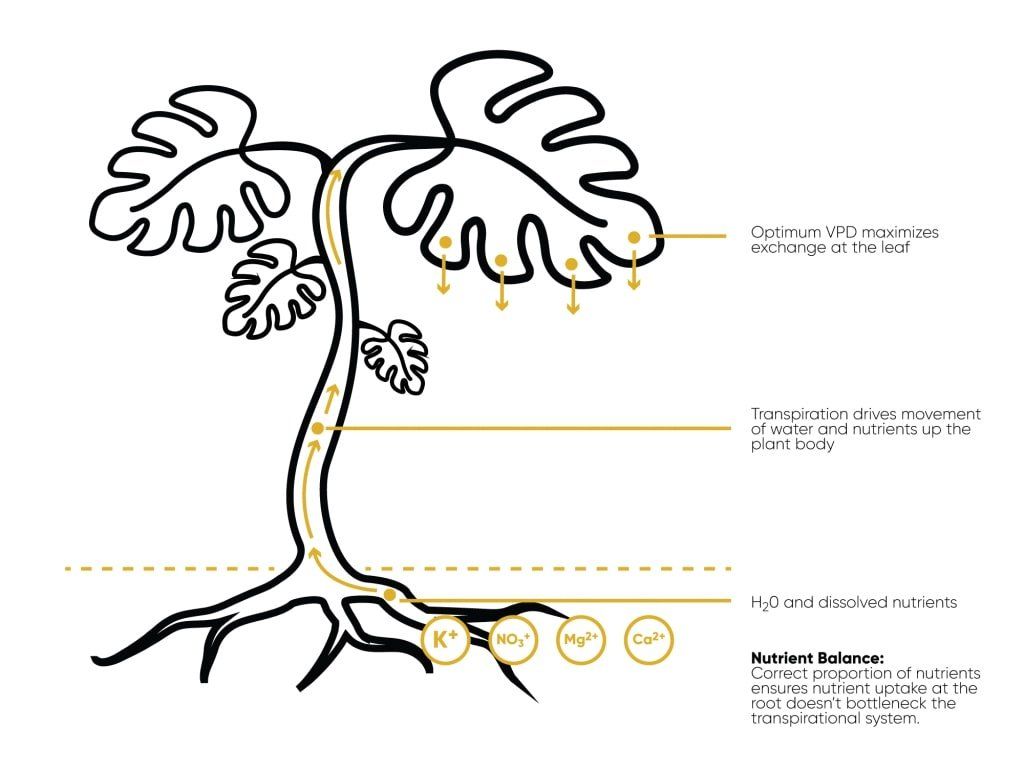

Water flows from high pressures to low pressures. Similarly, looking inside a leaf that is completely saturated (100% Relative Humidity value) and if the surrounding air is under saturated, the water will evaporate naturally from the leaf into the air as water vapor.

As water evaporates from the leaves, it creates pressure differences that force roots to absorb water together with nutrients and spread this all over the plant to grow properly and develop (transpiration).

Ultimately you are looking for a high ΔVPD value to promote transpiration otherwise low ΔVPD values will lead to water condensation over the plant leaves, thus increasing development of diseases.

You´ve decided to switch from HPS to LED grow lights. Now, you are wondering about how to take full advantage of your new LED lights to grow successfully.

This article provides a brief explanation on how to help you realign your plant growth process parameters when changing from HPS to LED grow light technology.

Five grow system variables to manage when transitioning from HPS to LED:

- Adapt the indoor grow room temperature

- Vapor Pressure Deficit (VPD)

- Effects on HVAC and Dehumidification

- Light Quality and Intensity

- Irrigation and Nutrition for Transpiration

Adapt the indoor grow room temperature (HPS to LED)

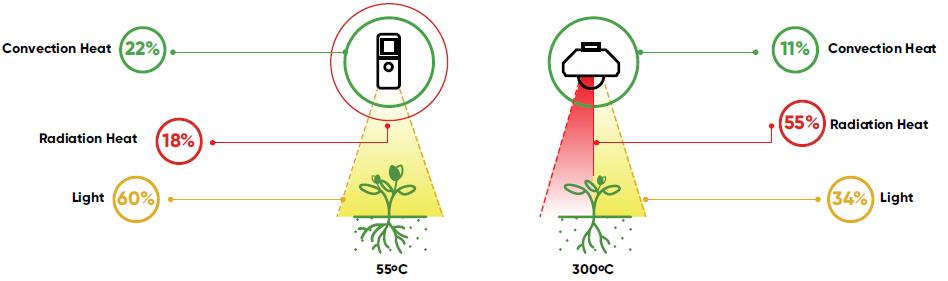

As a long-time indoor HPS user, you are aware about the radiant heat generated by HPS fixtures. The main source of this radiant heat is from the 860nm parts of the wavelength energy which dramatically raises the ambient temperature in any grow system which uses HPS lamps.

Adding to the radiant heat produced by the HPS lamps is the convective heat produced by the electronic power source (control gear) which also circulates inside the grow system

All produced radiant and convective heat will change the environmental conditions and it is fundamental that HVAC equipment is installed to maintain the desired ambient conditions for the particular type of plant you are growing.

This will lead to more energy costs in order to avoid biological plant damage, underdeveloped growth symptoms, problems with fast-drying grow medium and eventually; crop failure!

Of course, this is a clear sign that you need to move on with the transitioning from HPS to LED, replacing all your HPS fixtures by highly efficient LED technology.

Even if you need to balance all the heat loss to mimic the effects of your previously installed HID fixtures, the benefits are clear: Less radiant heat will be produced and less influence of convective heat will happen.

Effects on HVAC and Dehumidification

Your HVAC system settings were set up to control the generated heat from your previous HPS fixtures.

However, the new installed LED technology will operate at lower wattage generating 30-50% less heat whilst producing the same amount or more and better-quality photons.

The replacement of HPS with the new LED technology means less thermal waste, less HVAC air renewal cycles required, less HVAC maintenance interventions, less power consumption and less energy costs for an optimal growing condition at high quality light levels.

Note that your HVAC system dimensions were based on your previous HPS fixtures therefore it may not control humidity like before. To adjust this you may need to add dehumidification equipment.

Light Quality and Intensity

Your new LED fixtures also have a considerably higher light quality = different spectrum.

Its common to use two different bulbs with two different spectrums for vegetative and flowering stage. For example, due to the high number of red photons produced by the HPS bulbs, the effects on plants are to grow taller and develop thinner steams and leaves.

LED fixtures, mainly the ones that produce photons that falls in Full-Spectrum range, are revolutionary on helping growers provide plants more balanced spectrum without the painful and hard work of needing to change fixtures regarding the plant grow stages.

It is well proved that plants growing under a balanced spectrum, grow like the ones that grow under natural light, compared to the applied HPS fixtures.

Studies have shown that implementing Grow Light LEDs in operations previously using an HPS system will reduce lighting energy consumption by between 40-60%.

Without the radiant heat, growers can install LED fixtures closer to the plant canopy, however growers need to be concerned about the limits of light intensity that plant can receive.

As for Increasing the PPFD (Photosynthetically Active Photon Flux Density) to higher levels will be another challenge.

By increasing light intensity, you must help your crop absorb the extra produced photons by checking other environment parameters such as root temperature, humidity, CO2, watering, and nutrients, etc.

Not maintaining the main cardinal parameters of the plant growth process correctly can lead to plant photo inhibition and reducing photosynthetic capacity in response to excess light.

We recommend consulting our grow light strategies to help minimize the overexposure of your canopy and to understand the correct distance to hang your LED fixtures.

Irrigation and Nutrition for Transpiration

Note that with your new fixture’s technology (transitioning from HPS to LED), you are about to increase light intensity (PPFD levels) that generally leads to faster plant development.

Water and nutrients ration will need adjustments as the photosynthesis ratio increases, but with less radiant heat in the grow room, plant transpiration levels will also decrease. You may need to adjust irrigation levels. The plants may reduce transpiration rate up to 50% that means half of water will be consumed.

Remember that plant transpiration is the water moving inside your plant. Not only water, but water with nutrients. The ΔVPD set the velocity that nutrients together with water is spread internally in the plant.

Thus, a readjustment of all parameters should be done to prevent biological strangulation and ensure optimal growth. Note that the ‘signs’ that you used to read the plants when growing under HPS are now different.

But overall it’s an amazing and easy process. All for the betterment of your grow and Lumatek is all about the efficiency and here to help growers grow!