Elite Harvesting Solutions

ENVIRONMENT

When genetics are accounted for, the role of the grower is to provide the perfect conditions to maximize yield. Crop size can vary greatly subject to cultivation environment, whether that be indoor, outdoor or in a greenhouse. To boost harvests growers aim to provide optimal lighting, plant nutrition, temperature and humidity. This is much easier indoors, where light exposure, nutrients and climate can be closely controlled.

INDOOR GROWS

Lighting

A high-performance indoor setup typically provides 40-50W of artificial light per square foot of canopy, with anything less reducing yield. To calculate the amount of artificial light provided per square foot, growers need to divide the total wattage of all the lights in the room combined, by the size of the room.

Example

In a 15,000 ft2 grow room, with 5 x 75,000W lights (375,000W total):

375,000W / 15,000 ft2 = 25W per ft2.

In this example the amount of light available per square foot is nearly half that is considered optimal. As a result, it wouldn’t be surprising to achieve half a plant’s maximum yield.

If lighting has been insufficient, adjust the figure in the product selector for a more accurate reading:

30,000 ft2 with 25W per square feet may yield the same as 15,000 average ft2 of indoor grow.

Plant Nutrition

After light exposure, the quantity and quality of nutrients delivered to the plant is the second largest contributor to yield. Consequently, most commercial growers rely on hydroponics to ensure plants receive the required inputs to realize their potential.

If you have experienced under or over fertilization, leading to reduced growth, again adjust the figures in the product selector for more accurate results:

30,000 ft2 of indoor space under fertilized may yield the same as the 25,000 average ft2.

Heating and Ventilation

Temperature and air circulation are crucial, but often overlooked, environmental factors that impact yield. If the temperature or humidity is too high, plants may wilt and attract pathogens. If temperatures are too low photosynthesis decreases, and plant growth may slow or stop altogether.

If the climate has been unfavourable to cultivation amend the product selector input:

30,000 ft2 of indoor space with inadequate temperatures may yield 27,500 average ft2.

OUTDOOR GROWS

Outdoor operations are less confined by space and benefit from the best, and cheapest, light source available – the sun. For outdoor growers, forecasting yield and throughput is essential to accelerate the harvesting process. This reduces time to market and can provide farmers valuable early business opportunities, before supply meets demand later in the season.

Lighting

The geographic location of a farm is a consistent environmental factor, with latitude affecting daylight hours and the length of the season. Therefore, a farmer in Colorado may expect to produce more than the 2000 lbs of flower per acre, while a farmer in Washington may accept less. Annual flowering plants need eight hours of sunlight minimum, with unshaded south-facing sites maximizing the amount received.

If the season has few sunny days, adjust the data processed by the product selector for a better reading:

- 15 acres of plants with more sunlight than expected may yield the same as 20 average acres.

- 30 acres of plants in a season with inadequate sunlight may produce the same as 15 average acres.

Plant Nutrition

Site location also plays a major role in soil quality, which can be maintained and improved by fertilizer and irrigation. As the size of plants increases so does their ability to consume large amounts of water.

If plants haven’t been able to secure the right nutrient uptake, this should be factored into the product selector inputs for a more realistic result

.

- 15 acres of plants that experienced drought may produce the same as 5 average acres.

- 30 acres of plants with insufficient fertilization may equal the average yield of 25 acres.

GREENHOUSE GROWS

Greenhouses enable sunlight to reach plants and trap infrared radiation to heat the environment. Greenhouse growing combines aspects of both indoor and outdoor cultivation, offering a degree of climate control at a lower cost than an indoor operation. In conditions suited to outside growing, greenhouses can amplify the natural climate to boost yields with little added investment.

Lighting

Greenhouses harness the power of the sun, but supplemental lighting can be added to maximize photosynthesis. Supplemental lighting is often a necessity based on the site, with some locations enjoying more sunlight than others. For instance, a greenhouse in Vancouver may need double the additional lighting than in Arizona.

Based on your greenhouse’s lighting, amend the product selector accordingly for a more accurate reading:

- A 15,000 ft2 greenhouse without lights could yield that of the average 30,000 ft2 greenhouse.

Plant Nutrition

As greenhouses raise temperatures, plants grown in these environments need frequent irrigation. To maximize greenhouse yields facilities may be integrated with hydroponic systems. This ensures plants receive optimal fertilization, in addition to a constant supply of water free of hard minerals and chemicals.

If an irrigation system was implemented to maximize plant nutrition, you may receive a better reading with adjusted data:

- 10,000 ft2 greenhouse with hydroponics may produce the same as a typical 5000 ft2 greenhouse.

Heating and Ventilation

While greenhouses provide some protection from the elements, the climate is still significantly impacted by the outside temperature. As a result, many are rigged with heating and ventilation similar to an indoor grow.

If the greenhouse environment was closely controlled by extensive heating, ventilation and air conditioning systems, modify your input on the product selector accordingly:

A 20,000 ft2 climate-controlled greenhouse could yield the average of a 25,000 ft2 greenhouse.

EXPERIENCE

Every harvest is unique with different responses to environmental changes, nutrient solutions and training methods. When using the product selector, growers should predict harvest size based on genetic and environmental factors in combination with experience. If the environmental fluctuation wasn’t dramatic enough to have a significant impact on yield, for example, growers should use their best judgement and take this into consideration.

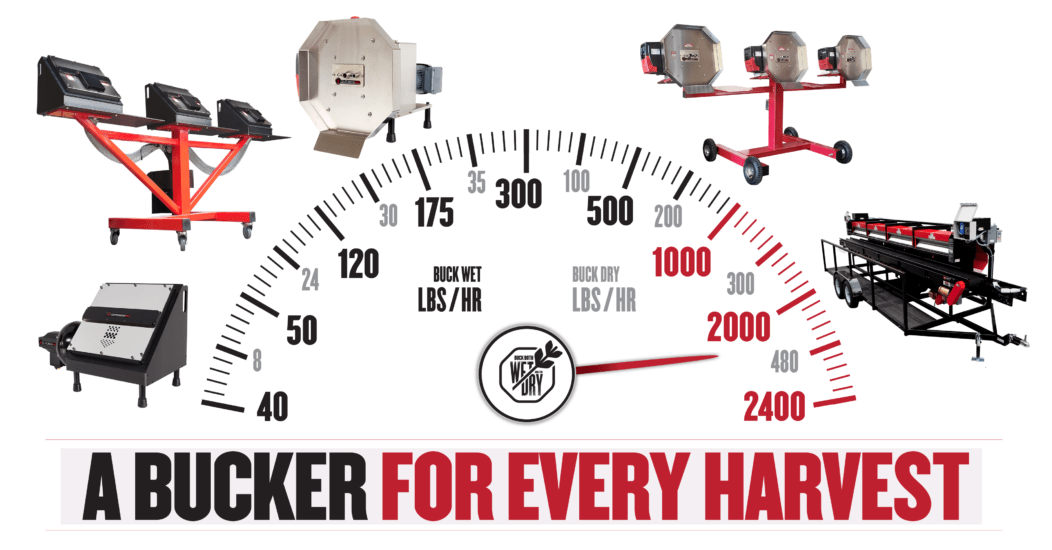

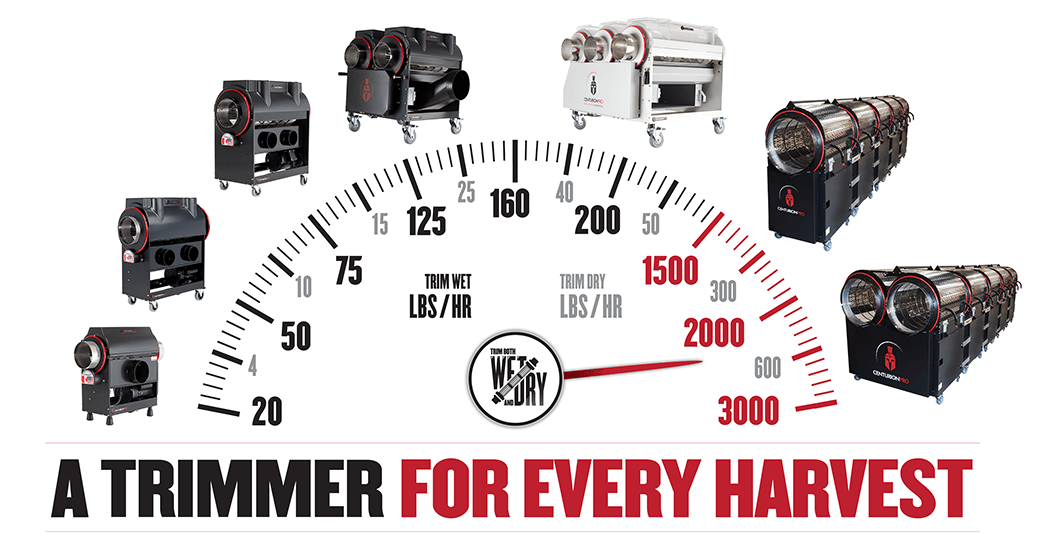

THROUGHPUT SPEED

While harvest size can be difficult to predict, the desired harvest time is usually a fixed deadline to fill a delivery window.

Analysing this timeline, in connection with expected yield, identifies the throughput capacity required in trimming and bucking machinery.

Example

20,000 lbs of plant needs to be trimmed in 40 hours:

20,000 lbs / 40 = 500 lbs/hr dry weight for required throughput

In this instance the grower may be best suited to the CenturionPro XL 10.0, which can trim 600 lbs of dry plant per hour.

LOOKING TO THE FUTURE

When forecasting yield and required throughput, outdoor farmers should accommodate for wider variations than their indoor and greenhouse counterparts, due to reduced environmental control.

For efficiency, the main motivation behind yield and throughput forecasts, it is always better to have too much harvesting capacity than too little.

As the industries continue to develop, investing in a bigger machine today may protect you against increased throughput tomorrow.

The best trimmers and buckers also have diverters, enabling growers to customize processing speeds during the expansion process.